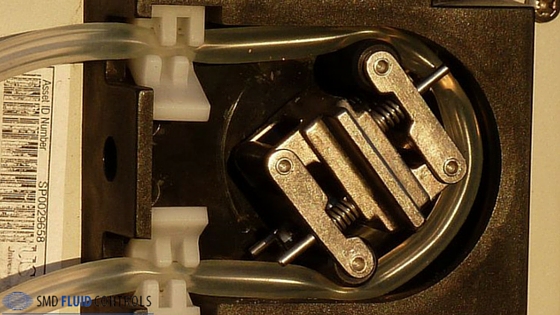

Peristaltic pumps are common in many industries, including medicine and surgery, testing and research, agriculture, engineering, wastewater treatment, food processing, and more. These positive displacement pumps consist of a flexible tubing fitted inside of a circular pump, with “rollers” fitted onto an interior rotor that compresses the tube and forces the pumped liquid through.

If you engineer, manufacture, or otherwise rely on peristaltic pumps, then one issue that needs to be dealt with is occasional fractures in a pump’s main tubing, resulting in loss of liquid and equipment contamination. While the risk of tubing fracture can’t be completely eliminated, sensors like those offered by SMD Fluid Controls can detect them early enough so that equipment can be shut down and necessary repairs made to minimize equipment damage and downtime.

Optical Level Sensors for Peristaltic Pump Leak Detection

Optical Level Sensors for Peristaltic Pump Leak Detection

Optical liquid level sensors work by emitting an infrared light from an LED in the tip. Under normal conditions, the light bounces and returns to a transistor in the tip, but in the presence of liquid this operation is interfered with and a switch is triggered.

Leaks in peristaltic pump tubing can be detected with optical level sensors like the OS950 mini plastic model from SMD Fluid Controls. The sensor is fitted into the pump’s sump area, and if leaking liquid is present in enough volume, it interfered with the function of the sensor, and an emergency shut-off is activated. Optical level sensors are ideal for peristaltic pumps because they are economical, durable, compact, and feature no moving parts.

SMD Fluid Controls can also create custom liquid flow meters and flow sensors for use in peristaltic pumps and other applications.