As worldwide demand for energy grows, more and more consumers in the business, industry, and private sectors are relying on gas-powered turbine generators to provide needed electricity. Unfortunately, the energy output and overall operating efficiency of these generators are significantly reduced during hot weather – exactly the time when the demand for electricity is highest. One solution to this problem, known as turbine inlet air cooling (TIAC), involves cooling a generator’s intake air by any of several methods. Let’s take a closer look at the issue and see how SMD Fluid Controls can help with ultrasonic float switches.

As worldwide demand for energy grows, more and more consumers in the business, industry, and private sectors are relying on gas-powered turbine generators to provide needed electricity. Unfortunately, the energy output and overall operating efficiency of these generators are significantly reduced during hot weather – exactly the time when the demand for electricity is highest. One solution to this problem, known as turbine inlet air cooling (TIAC), involves cooling a generator’s intake air by any of several methods. Let’s take a closer look at the issue and see how SMD Fluid Controls can help with ultrasonic float switches.

How Hot Air Affects Gas Turbine Generators

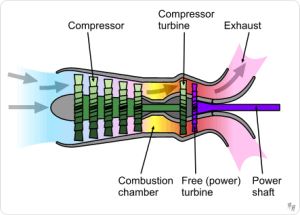

A gas turbine is a type of internal combustion engine which takes ambient air from the atmosphere and passes it through a compressor to bring it to high pressure. An injector sprays liquid fuel into the compressed air, which is then ignited to generate a high-temperature gas flow to drive shaft work output. When used for power, this work output is used to operate an electric generator.

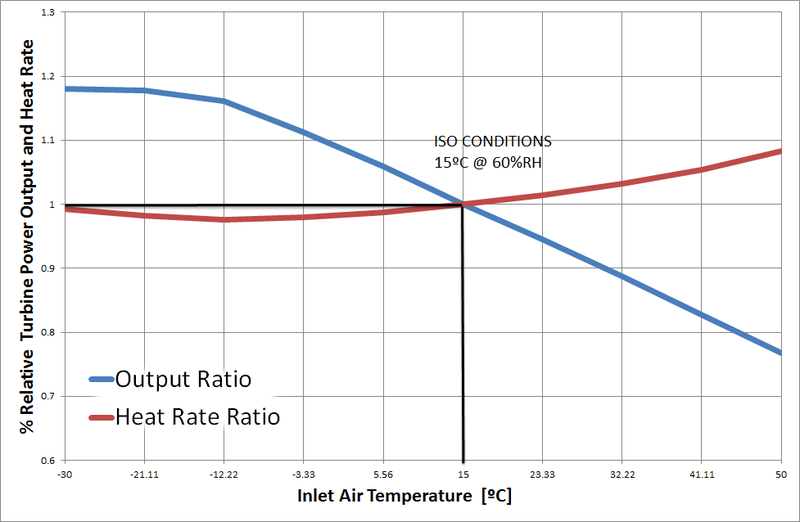

As the temperature of atmospheric air increases its density decreases, meaning air mass goes down and more fuel is required to keep shaft output at a constant level. This is due to lower levels of oxygen in lower air densities.

Turbine inlet air cooling is any of several processes by which atmospheric air is cooled as it enters the turbine’s intake, increasing fuel efficiency and operational output. There are several techniques for TIAC, some of which are more effective than others.

Methods and Solutions for Turbine Inlet Air Cooling

The simplest method of TIAC may be passing intake air over a cool liquid-soaked medium as it enters the turbine.

A more sophisticated solution involves water misting – atomized water droplets are sprayed at high pressures into the air intake, providing more precise control of intake air temperature and performance output. Compression chillers, which circulate coolant through a chilling coil near the air filter similar to a standard air conditioner, can also be used with great effectiveness. Thermal energy storage tanks are sometimes used in combination with these or other methods to store chilled water for later use.

Liquid & Temperature Management Sensors: The Perfect Solutions

In almost any case, turbine inlet air cooling requires precise liquid controls to function properly. Any TIAC system will, therefore, be dependent on precise sensors to detect liquid level, temperature, pressure, and other dimensions according to system specifics. Sensors from SMD Fluid Controls can help provide these and other measurements for turbine generators, or any other mechanical system that relies on active or stored liquids. SMD offers numerous off-the-shelf solutions in addition to custom design solutions.