Most liquid level sensors such as traditional float switches need to be immersed at one point or another in the liquid medium being measured. With applications involving liquids like water, this is not an issue. But what about applications involving more difficult materials?

Most liquid level sensors such as traditional float switches need to be immersed at one point or another in the liquid medium being measured. With applications involving liquids like water, this is not an issue. But what about applications involving more difficult materials?

When sensors are required to measure tank levels for difficult liquids such as acids, gasoline, wastewater, manufacturing slurries, and others, prolonged exposure may result in unacceptable damage.

This is when non-contact liquid level sensors are needed.

Non-Contact Sensing Using Ultrasonic Level Sensors

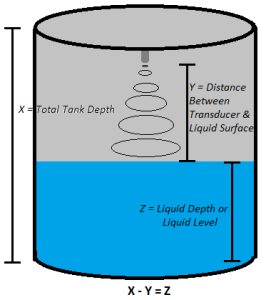

One highly effective way to measure liquid levels in non-contact applications is the use of ultrasonic liquid level sensors. Ultrasonic liquid level sensors are mounted at the top of a tank or vessel and use ultrasonic sound waves to calculate the depth of liquid. Agitated liquids can interfere with this process, but the use of still pipes can attenuate this when required.

Ultrasonic level sensors are also capable of continuous level measurement in addition to point-level monitoring, another advantage over more traditional float switches.

FL50 – Chemical Resistant Plastic Ultrasonic Point Level Sensor

FL50 – Chemical Resistant Plastic Ultrasonic Point Level Sensor

Made out of durable polypropylene plastic, the FL50 ultrasonic level sensor is ideal for hydraulic fluids, oils, slurries, and more. The FL50 features a relay output with 1 A max switching current, 5-15 max voltage, temperature maximum of 90°C, and a max pressure of 150 PSIG.

FL-LL – Stainless Steel Ultrasonic Liquid Level Sensors

FL-LL – Stainless Steel Ultrasonic Liquid Level Sensors

Like the FL50, the FL-LL line of stainless steel ultrasonic switches is ideal for use with wastewater, industrial slurries, oils, acids, food, processing chemicals, and more. Unlike the FL50, though, the FL-LL series can operate in up to 5,000 PSI. Switches in the FL-LL line include the FL-LL25, FL-LL50, and FL5K. Each has unique configurations and outputs suited to particular integrations and applications.

Contact SMD Fluid Controls

In addition to these standard options for non-contact level sensors, SMD Fluid Controls offers custom design and OEM manufacturing services. If you’re working with a particularly difficult application, let the team at SMD Fluid Controls help you to find a solution.