In liquid level measurement, sensors can be thought of as having two general classes: point-level and continuous.

Point-level liquid level sensors detect the absence or presence of liquid at a certain point. Overflow alarms and low-level alarms to detect leaks are examples of applications that use point-level sensors.

But for applications where precise liquid levels need to be known at any given point, especially when they fluctuate frequently, continuous liquid level sensors are required. Fuel level sensors are an example of a continuous level sensor.

If you’re looking for continuous liquid level sensors for any industrial application, SMD Fluid Controls has a number of options.

Get in touch with SMD Fluid Controls or keep reading to learn more.

Ultrasonic Level Sensors for Continuous Liquid Level Measurement

One option offered by SMD Fluid Controls for continuous level measurement is the FL series of ultrasonic level sensors.

Ultrasonic liquid level sensors work by emitting an ultrasonic pulse of sound. When the sound bounces off the liquid surface, it bounces back and returns to the transmitter. Using the speed of sound, the distance from the transmitter to the liquid surface—and depth of the liquid within the tank—can then be measured.

By continuously emitting ultrasonic sound waves, continuous level measurements can be recorded.

Ultrasonic units also have the advantage of being non-contact liquid level sensors, ideal in applications involving corrosive or otherwise difficult liquids.

Hydrostatic Pressure Sensors for Continuous Liquid Level Measurement

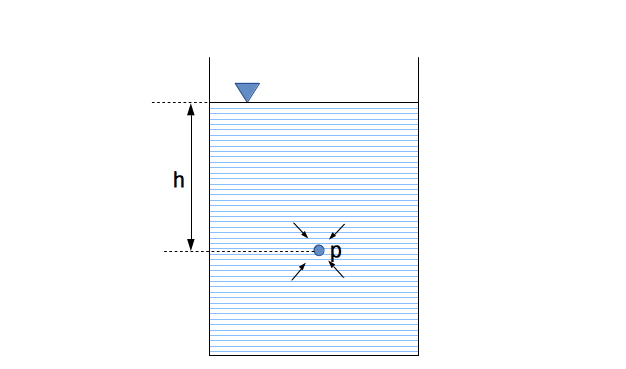

Hydrostatic pressure level sensors are placed at the bottom of a tank or vessel attached to a long lead line. The transducer records the pressure exerted on it by the surrounding liquid and is then able to calculate the total liquid volume and levels within the tank or vessel.

Because hydrostatic pressure sensors continuously measure pressure levels, they are ideal for continuous level measurement.