Maintaining safe operating conditions in a process vessel is critical to the safety of employees and the integrity of consumer products. In many cases, conventional metal and polymeric float switches will be able to complete the task, however, in more corrosive environments they are at a disadvantage. Industries such as petrochemical, food, and pharmaceutical use corrosive liquids that can compromise the utility of our conventional liquid level devices.

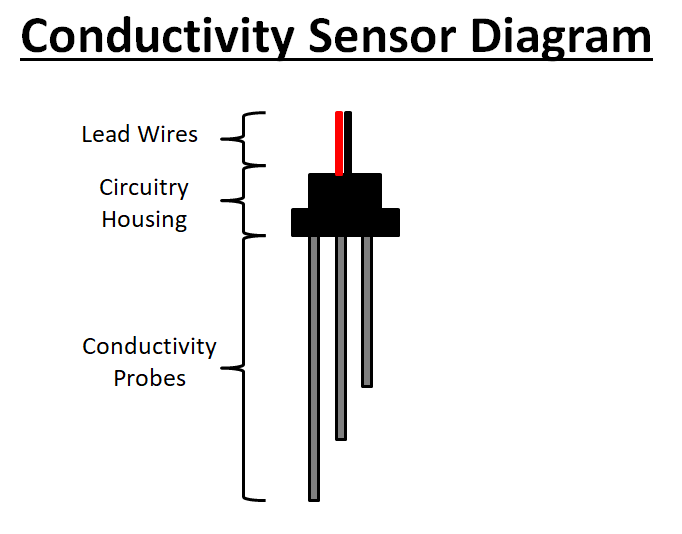

The diagram below shows the three sections of the conductivity sensor: the two lead wires that protrude from the top of the sensor, the housing of the circuitry, then the probes that are used to complete the circuit. When the probes come into contact with the solution, which is highly ionic and conductive, the ions in the solution complete the circuit as if the two probes were to be connected.

The diagram below shows three different variations of the conductivity sensor. Sensor “A” is a single level conductivity sensor. This works with a metal tank that is grounded and used to complete the circuit of the sensor. When the water level reaches the probe, the sensor is then activated by having the ions in the solution complete the circuit between the probe and the tank.

In sensor “B”, the tank does not need to complete the circuit. The ions in the solution bridge the two probes together once both probes touch the liquid.

Finally, sensor “C” is a multi-level sensor which can be grounded by the tank, and also doesn’t need to be. By having two probes at the same length, the tank will not need to be grounded. Each subsequent probe will complete the circuit in reference to the longest probe, allowing for multiple liquid levels to be detected on a single sensor.

There are a number of advantages that these sensors have compared to tradition liquid level sensors.

- Stability in highly corrosive environments with acids and bases such as sulfuric acid and sodium hydroxide with the use of probes constructed of monel, titanium, and Hastelloy C to name a few.

- There are no moving parts and relies on a complete circuit for actuation.

- Generally less expensive equipment materials and installation

- Can incorporate multiple probes for multiple levels of control

- Minimal maintenance due to simplistic design which also prevents fouling of the probes.