As the world’s energy demands grow and fossil fuels become both scarcer and more controversial, one option for energy production promoted by many is a nuclear power. Of course, nuclear power isn’t without its controversies as well, due largely to high-profile accidents like those at Chernobyl and more recently in Fukushima, Japan.

As the world’s energy demands grow and fossil fuels become both scarcer and more controversial, one option for energy production promoted by many is a nuclear power. Of course, nuclear power isn’t without its controversies as well, due largely to high-profile accidents like those at Chernobyl and more recently in Fukushima, Japan.

If nuclear power is to be an option for humanity’s future, ensuring proper function and safety of all plants will be absolutely crucial. That’s why liquid level sensors for nuclear plants are going to be increasing in demand in years to come. To illustrate, let’s look at the case of one notable power plant failure.

Three Mile Island Accident

The partial nuclear meltdown that occurred in March of 1979 at Pennsylvania’s Three Mile Island was the worst nuclear accident in the United States’ history.

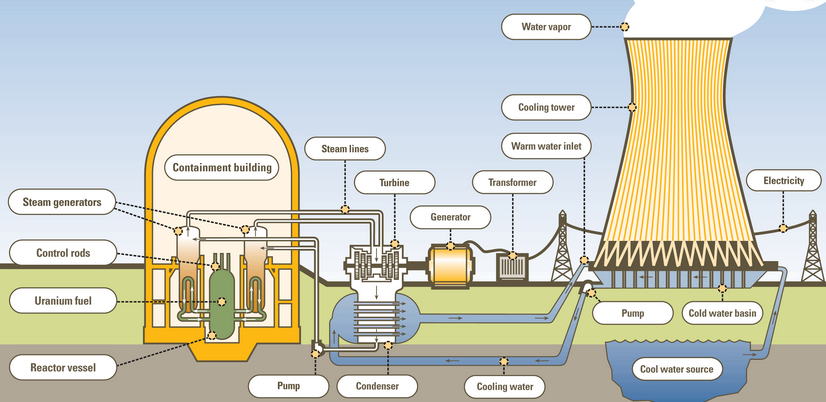

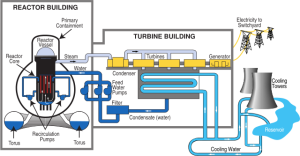

The accident was caused by a malfunction in a secondary cooling circuit in the TMI-2 reactor, which resulted in the reactor’s primary coolant rising dangerously in temperature. As a safety precaution, the reactor then shuts down automatically, with control rods inserted to stop the nuclear chain reaction.

A relief valve was activated, but rather than closing it stayed open, leaking coolant. Operators assumed the valve had closed because a close signal had been sent to it; however, there were no instruments to gauge the valve’s actual position. The loss of cooling water caused injection pumps to send replacement water, which then escaped as liquid and steam through the open valve into the pressurizer.

Operators reduced the flow of replacement water, misreading the levels in the pressurizer as indicating an over-abundance of water in the whole cooling system, rather than an open valve. This confusion is what led to the accident.

While the incident was a perfect storm of technical glitches and human error, one thing that’s certain is that had the cooling system been properly outfitted with liquid level sensors throughout, rather than relying only on the levels in the pressurizer, operators would have known more about the leak and the status of the cooling system as a whole. This likely would have prevented the meltdown.

It’s no surprise then, that in the aftermath the Nuclear Regulatory Commission ‘s Advisory Committee on Reactor Safeguards stated:

“The Committee believes that it would be prudent to consider expeditiously the provision of instrumentation that will provide an unambiguous indication of the level of fluid in the reactor vessel…”

Ultrasonic level sensors, then a new development, were recommended.

Specific Level Sensor Applications for Nuclear Plants

Spent Fuel Pools

Every 12 to 18 months up to 1/3 of a reactor’s fuel load is removed and replaced. Old rods are then stored in deep pools of water to cool down and be provided with radiation shielding before being sent for reprocessing or storage.

This water must be cooled continuously by recirculation, a process that requires high-level and low-level alarms, as well as more general level sensing to guard against leaks.

Emergency Coolant Tanks

Emergency coolant tanks store extra coolant water for use if a reactor’s normal cooling systems leak or are interrupted (a condition which could be detected through low reactor coolant levels). They are vital to the prevention of meltdown in many situations, as is accurate level control. Especially important is the detection of low levels in emergency tanks, as this triggers pumps to bring coolant from other sources.

Ultimately, as nuclear power relies on boiling water to power turbines and circulating water to cool its dangerous nuclear material, water is perhaps the most crucial component of the process, and level sensing is vital at numerous stages.